|

This new glass passion came about by accident! People give me glass windows, shelves, and doors to use as up recycled raw material. A couple of years ago I had a piece of glass that I planned to use to create a bird bath. As I tried to cut the glass, it shattered into tiny bits. This is when I discovered it was tempered glass, also known as safety glass. Tempered glass is made by progressively heating and flash-cooling glass to create inner stresses. This allows the glass, if broken, to break into little pieces rather than long, sharp shards.

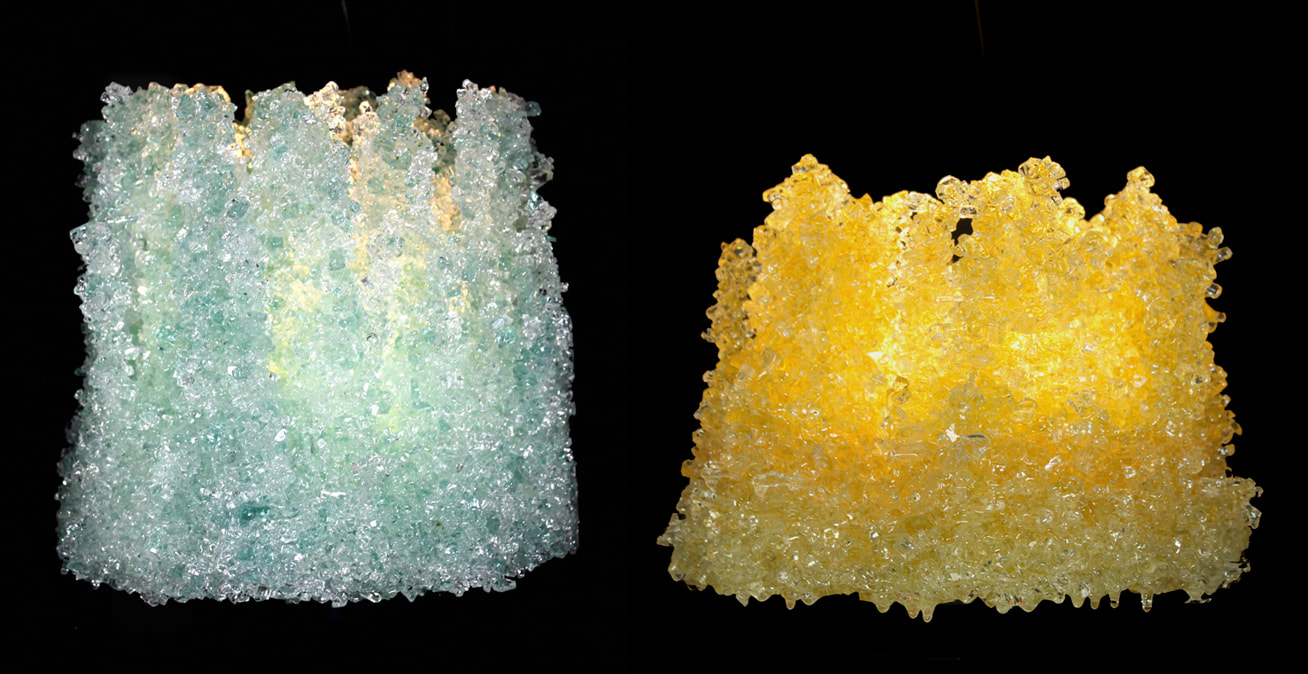

As I was sweeping up the shattered pieces, I realized the glass had an amazingly beautiful ice blue/aqua color when the small pieces were grouped together. I knew I had to find a way to use this beautiful substance. Always mindful of the transparent nature of raw glass, I thought a lamp might be the perfect design. However I faced a problem: How could I stick together these tiny glass pieces to form the large piece I imagined? In the kiln, glass starts to adhere to itself when fired to 1200 degrees. The heat softens the surface of the glass in order to fuse it together. In the case of my lamps, fusing the glass in the kiln would make a big blob as the edges softened and rounded. So I started experimenting with alternate “cold fusion” methods to preserve the beautiful crystalline appearance of the shattered glass. I tried various art mediums and glues until I finally settled on an epoxy resin for the best results. The initial process is like the sand candles many of us have made, by using gravity to create the piece upside down. After the glass window or door has been cleaned and shattered, I collect the pieces in a large container. Prepared epoxy resin is then poured into the bucket and gravity takes over, creating various spires and shapes. The size and design of the lamp is influenced by both the preparation and the pouring method of the epoxy into the broken glass. After hardening, the lamp is lifted out of the bucket and its shape is further refined by hand sculpting. After the shape is sculpted and the sharpest pieces are removed, the lamp gets an extra layer of the resin to protect against glass cuts. The larger pieces become lamps and the smaller ones become candle holders. The finished products look like little crystal glaciers. The natural glass color ranges from very pale turquoise to darker blue-green, depending on the manufacturing formula of the original glass. I primarily work with this natural color because it’s so beautiful but can happily make customized colors. The turquoise lamp is the natural color, and the gold lamp has added color. ~ Morgan Bell

22 Comments

|

Artworks InspirationsOur artists share their experiences and inspiration with you here. Comments and questions are welcomed! Archives

June 2024

Categories

All

|

|

Follow us on Social Media:

Signup for Our Monthly Newsletter:

|

© Copyright 2024 | All Rights Reserved | Artworks Gallery

RSS Feed

RSS Feed